What Is a Motorcycle Slipper Clutch? (Explained)

Disclosure: We may get commissions for purchases made through links in this post.

Out-of-norm traffic conditions and racetracks have a couple of things in common — tendencies for panic braking and accidental downshifts, both leading to rear-wheel lock-up. Almost all of us have gone through these situations at some point in our riding lives — not the nicest experience when you are in the middle of the road. Thankfully, OEMs have started equipping base motorcycle models with a slipper clutch to address these challenges.

So, what is a motorcycle slipper clutch anyway?

A motorcycle slipper clutch (a.k.a. assist slipper clutch or back-torque limiter) is a feature in most high-performance two-wheelers that lends to seamless downshifting into corners by progressively disengaging the clutch basket from the clutch center according to the amount of back-torque.

We will not only define what a slipper clutch is but also compare it against similar features. We will also touch on its highlights and lowlights and tips on getting the most out of the said add-on.

You may not see a need for this option at the moment, especially if you have stellar throttle and clutching skills. But if you are new to using this feature, then today’s guide is for you!

What Is a Slipper Clutch on a Motorcycle?

The slipper clutch (a.k.a. assist slipper clutch or back-torque limiter) is a motorcycle feature comparable to a standard manual clutch but designed to limit wheel hop when slowing down or downshifting into corners. It is fitted between the power mill and the transmission, with size and durability contingent on the piston displacement and specific characteristics of a motorcycle.

This clutch type is predominantly available in larger-displacement two-wheelers. However, a handful of smaller-displacement bikes currently have it: Kawasaki’s Ninja 300, TVS Motor’s Apache RTR 200, Bajaj’s Dominar 250 and 400, and KTM’s Duke 390 series (to name a few).

This technological feature was born in motorsports, with its first application found on John Gregory and TC Christenson’s Hogslayer. The said twin-engine Norton top-fuel drag bike produced 320 bhp and a top speed of 180 mph (290 km/h). It also held many records plus a string of world championships in its name during the ’70s.

Because of its technological innovations (including pioneering slipper clutches in Moto GP racing motorcycles), this drag machine is referred to by enthusiasts as “The Unapproachable Legend.”

Functionally, the slipper clutch is considered a safety device since it smoothens imperfect clutch inputs of novice riders. For more experienced motorheads, it takes the fuss out of downshifting high-compression V-twin engines, high-end performance bikes, and the like — essentially what makes it possible for MotoGP riders to drop three to four gears within seconds on the track.

How Does a Slipper Clutch Work on a Motorcycle?

The easiest way to understand is by referencing how a bicycle works. When you stop pedaling, a bike would still move ahead, right? The reason for that continued movement is the bicycle drivetrain “slipping” when its speed is faster than the speed of your legs.

The same happens with a slipper clutch on a motorcycle — except the latter will slowly try to engage plate after plate until it is compatible with the engine speed.

In light of the above analogy, however, it does not necessarily follow that a motorcycle slipper clutch alone would suffice in matching the input and output shaft speeds in the transmission. In fact, it does not really do anything in that aspect.

What the slipper clutch fundamentally does is reduce wheel hop or skidding of the back wheel when engine braking exceeds the amount of rear-wheel traction.

This is why throttle blipping and rev matching are still required to momentarily unload the transmission (remove torque on the shafts) and open a window for a clean shift. Failure to do a throttle blipping would destabilize the motorcycle (especially those with stock ECU) since a fair amount of engine braking is still present before the slipper clutch comes into play.

Similarly, skipping on doing a rev match because you have a slipper clutch may reduce the likelihood of a skid or crash due to rear-wheel lock-up but will not entirely eliminate the possibility.

Now, you may think that a standard clutch coupled with a good command of engine braking can do what a slipper clutch does too, and you are absolutely right! However, significant design and functional differences exist between the two setups, as you are about to learn in the next section.

Slipper Clutch vs. Normal (Wet/Dry) Clutch

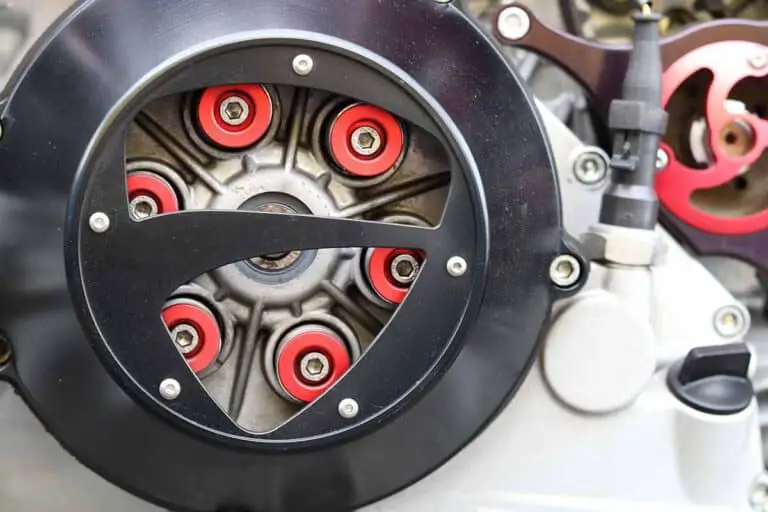

While essentially similar in function and main components, a motorcycle slipper clutch is like a standard slipper clutch but on steroids — and rightfully so due to the design of its clutch hub. Slipper clutch hubs are disassembled, with the base (where the ball and ramp are) on the right side and the hub (where the ramp, engagement dogs, and ball bearings are) on the left side.

Noticeably, it has ramps sandwiched between the inner basket and pressure plate, according to Motorcyclist — something not present in an ordinary clutch assembly.

In normal operation, engagement dogs push on each other, driving the motorcycle forward as a standard clutch would. But during hard deceleration or braking, the torque forces the ramps together.

Meanwhile, the ramps slide on each other when absorbing engine braking force — lifting the clutch hub from the base and in the direction of the pressure plate. This mechanism is called “spring loaded ball sliding up ramp.”

The above process enables the clutch to partially disengage when overloaded with engine braking force. This capability is not inherent in a conventional clutch design, which solely relies on rider input to engage and disengage the pressure plate clutch discs.

Clutch Stack Height

Clutch stack height is another factor that is more critical in a slipper clutch than a standard manual clutch. A motorcycle slipper clutch would require a stack height of approximately 1 mm more than the distance between the clutch hub base and the pressure plate to operate efficiently. On the other hand, a normal clutch would not have such stringent prerequisites.

The order of clutch plates also differs between slipper and standard clutches mainly because the slipper clutch hub lifts off the base — more so when clutch plates include special friction plates and judder springs. In such conditions, the first plate closest to the engine is a friction plate, followed by a steel plate, then a special friction plate, and (finally) judder springs.

A standard wet multi-plate clutch (for instance) only utilizes a series of alternating fiber and steel discs (usually with spline grooves) to engage the gearbox to the engine.

Slipper Clutch vs. Quickshifter

Like a slipper clutch, a quickshifter is not a standard feature in motorcycles either. But I think it best to differentiate the two since they come up in many forum discussions and online searches.

Functionally, a motorcycle slipper clutch and a quickshifter are opposites of each other. While a slipper clutch assists with downshifting, a quickshifter aids in upshifting. The former still utilizes the clutch (just a different hub design) to downshift during hard deceleration, while the latter achieves seamless upshifts without pulling in the clutch or rolling off the throttle.

Lastly, a slipper clutch still requires throttle blipping. Conversely, a quickshifter sometimes comes with auto-blipping, eliminating the need to throttle blip manually.

Quickshifters kill the engine momentarily but in a period humanly impossible to do (we are talking about 15-50 milliseconds!). During this window, the load lifts off the gearbox, allowing a rider to upshift the gears without backing off the throttle.

In addition, these gadgets do not unsettle the suspension, lending to a motorcycle’s stability when making a turn. As if that were not enough, a quickshifter is more fuel-efficient than a motorcycle slipper clutch.

Slipper Clutch vs. Assist Slipper Clutch

An assist slipper clutch (a.k.a. slip and grip clutch) is basically a motorcycle slipper clutch but with an “assist” function. With a slipper clutch, ramps allow clutch slippage when a motorcycle decelerates aggressively but do not provide the same support when the bike speeds up.

But with the assist slipper design, reverse ramps lock in and pull the pressure plate in when the motorcycle accelerates. It also typically pairs with lighter springs since the clutch lever requires less force from a rider to engage the clutch assembly.

Motorcycle Slipper Clutch Pros and Cons

Pros

- Serves as a damper between the engine and transmission, effectively decreasing transmission wear and tear

- It makes for less rider input when it comes to downshifting and operating the clutch — thanks to lighter clutch springs that translates to reduced clutch pull and less rider fatigue.

- If the gear selected does not match the motorcycle speed, the slipper clutch helps make for gentler and smoother chassis behavior by partially disengaging or “slipping” to cancel the force sent from the rear wheel to the engine.

- Allows the rider to concentrate on body posture (among others) without having to fully focus on clutching or worry about accidental downshifts

- Offsets the lack of static load meant to push the tire into the tarmac

- Considerably reduces engine braking effects such as jerking, traction loss, driveline lash, and rear-wheel lock-up when downshifting too quickly.

- It helps spirited riders make the most of their two-wheeler’s transmission and carry more speed in corners when riding hard on racetracks or twisty roads.

- It comes in handy on slick surfaces where a rider may downshift accidentally.

- It prevents the engine from over-revving or seizing.

- Reduces stress on the bike’s suspension by absorbing engine braking force

- It eliminates the need for gradual deceleration and braking in slight corners (only applies to certain situations)

Cons

- Quite difficult to install and service, as a slipper clutch is mechanically complex

- A very exacting component — it will not work if not adjusted according to requirements

- It cannot be retrofitted due to its complex design.

- More expensive than a standard/normal clutch, with average prices of approximately $1,000 each per Motor Biscuit

- It may be counter-intuitive when engine braking force is needed to slow down a motorcycle.

- If added as an aftermarket option to a bike whose engine and brake competencies are incompatible, it often requires tweaking the transmission to provide the level of braking capabilities that will match the engine’s power.

Can You Bump/Jump Start a Motorcycle with a Slipper Clutch?

Ultimately, the answer to this question depends on several factors. One of them is the slip setup of your clutch. A setup that is too tight and not permitting much slip may make it impossible to bump-start your two-wheeler — although some motorheads claim using a higher gear and dumping the clutch is a proven workaround to this dilemma.

The other facet to consider is the voltage requirements of certain components that bring the motorcycle to life. High compression engines, multiple cylinders, electric fuel pumps, and ECU-controlled EFIs are some examples.

Because these components require priming, voltage, and a specific amount of amperage, bump starting may become a problem (even for conventional clutch assemblies). But jump-starting should not be an issue if you have sufficient current/amperage on the starter as you would with a charged battery.

How to Use the Slipper Clutch on a Motorcycle

There is no cookie-cutter approach to using a motorcycle slipper clutch, although the timing is of the essence. Going for a buttery smooth transition is another top consideration.

As established earlier, you will need to temper the benefits of this tech feature with correctly executed throttle blipping and rev-matching. But even these actions will not work the same way for everyone. For instance, a vacuum-operated slipper will feel like it is losing vacuum, even when you blip the throttle accordingly. So, it largely depends on riding conditions.

If you are on the track, make sure to use the slipper clutch before you are leaned over on the corner entry. If you are already in that spot before engaging the clutch and blipping the throttle, you will get rear-tire sliding and lose rear stability altogether because your timing is just too abrupt. You may also have to ditch those earplugs to hear what is happening to your engine better.

However, a motorcycle slipper clutch and its benefits may not make much difference for street riding. Nonetheless, timing is still key. The only setback with on-road driving is that there is not much information to go on. Based on forum discussions and the like, riders rarely find themselves in dicey situations when riding on pavement, even on slippery roads.

Vacuum-operated Slipper Clutches

For this type of slipper clutch, there are generally two ways to go about downshifting (see below):

Scenario 1:

- Push hard to a bend.

- Bang on the brakes.

- Slow down.

- Downshift one gear at a time.

In this first scenario, you will unsettle your motorcycle each time you downshift a gear. This is to be expected, although it is a situation most riders would want to avoid. If you are among these riders, you may prefer a different approach (see below):

Scenario 2:

- Push hard to a bend.

- Bang on the brakes.

- Slow down.

- Downshift two gears at once while doing a throttle blip.

- Close the throttle and let the engine RPMs rise and sort themselves out.

In this other scenario, all you did was brake, downshift, settle for the turn, and let the slipper clutch regulate the rising revs and match the engine speed and wheel speed. Sure, you will lose rear-wheel traction since all weight is on the front. But you will also be able to keep enough vacuum for your slipper clutch as the throttle is completely shut while the motorcycle adjusts to your selected gear.

Again, these steps only apply to the track and take real effort to work. They are also specific to vacuum-operated slipper clutches and would greatly differ from mechanical motorcycle slipper clutches.

Conclusion – What Is a Motorcycle Slipper Clutch?

A motorcycle slipper clutch — whether an auto slipper clutch or any other clutch setup — should never be treated as something to rely on. Yes, it will help balance out incorrect rider inputs and reduce rear-wheel hop, but it should never be used to override downshifting.

Despite being a safety feature, slipper clutches do not make your two-wheeler impervious to engine jerking. It is best to think things through before getting one, especially when your motorcycle does not come stock with this feature.